Pneumatic knife gate valves play an important role in industries that handle fluid or material applications. Besides controlling the flow of fluids, slurries or solids, these valves are designed with safety features. This article explores the built in safety measures found in knife gate valves and highlights their function in ensuring operational safety and preventing potential hazards within industrial environments.

Introduction to Pneumatic Knife Gate Valves

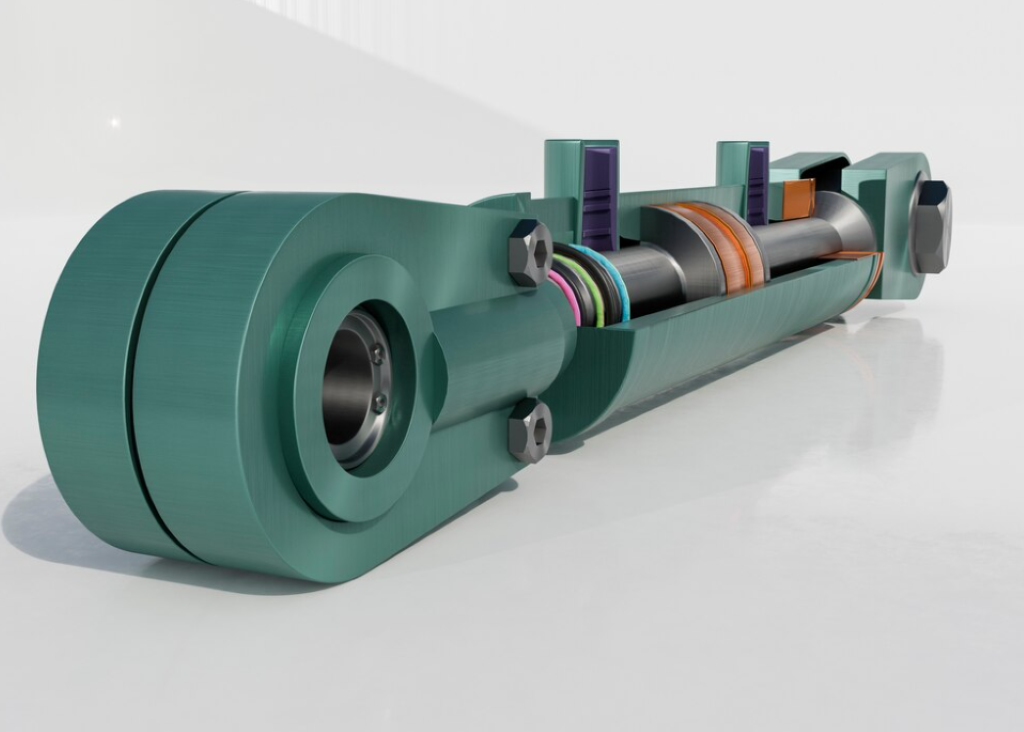

Pneumatic knife gate valves are specifically engineered to handle abrasive materials, viscous fluids and substances containing solids. Their unique design, resembling an edged knife along with the use of pneumatic actuation enables reliable and precise flow control in applications where traditional valves may face difficulties. Here is the link to a material handling equipment manufacturer that produces these valves, attached for your reference.

Inherent Safety Features

- Emergency Shut Off Capabilities: Pneumatic knife gate valves are equipped with rapid actuation mechanisms that enable emergency shut off when necessary. This feature is critical for preventing spills, leaks or accidents during situations that demand a halt to the flow.

- Fail Safe Positioning: In case of power failure or loss of pressure, these valves are designed to default to a safe position. Typically this would be either an open or close position based on system requirements. To guarantee the safety of the valve, measures are taken to maintain its known state effectively averting any potential risks.

- Prevention of Leaks and Effective Sealing: Pneumatic knife gate valves incorporate sealing technologies to ensure airtight operations. These tight seals serve the purpose of preventing any leakage, thus minimizing the chance of contamination and safeguarding the well being of workers.

- Resistance Against Corrosion and Wear: The valve’s ability to resist corrosion, abrasion and wear contributes to safety. By utilizing materials and coatings, these valves retain their integrity over time, ensuring long lasting reliability while preventing any potential failures resulting from material deterioration.

- Monitoring Positions and Providing Feedback: Many modern pneumatic knife gate valves are equipped with position monitoring sensors or feedback systems. These features offer real time information about the valves position and performance. This valuable data aids in fault detection and facilitates maintenance practices. Guarantees proper operation.

Applications for Ensuring Safety

- Wastewater Treatment Plants: In wastewater treatment facilities, knife gate valves prevent spillage or leaks of sludge or abrasive substances. This not only maintains safety but prevents environmental contamination as well.

- Mining and Minerals Processing: These valves have a function in controlling the flow of slurries during mining operations. By preventing leaks or spills that could pose risks to personnel and equipment, they contribute significantly to safety.

- Chemical and Petrochemical Industries: These industries heavily rely on knife gate valves to enhance safety measures. These valves handle substances, preventing leaks and safeguarding workers as well as the overall integrity of the processing plants.

Compliance and Standards

To ensure compliance with industry standards and certifications, pneumatic knife gate valves undergo evaluations by organizations like the Manufacturers Standardization Society (MSS). By meeting safety, performance and quality requirements, these valves provide an added layer of assurance.

The Findings

The incorporation of safety features in knife gate valves is essential for accident prevention, environmental protection and operational integrity across industrial sectors. Their ability to promptly respond to emergencies, resist leaks under conditions and deliver consistent performance makes them indispensable components when it comes to ensuring workplace safety while dealing with challenging materials or fluids. As industries progress over time, continuous improvements and advancements in the safety features of knife gate valves will continue to enhance both workplace safety and operational efficiency.